How to Build a Plastic Box

If you’re new to box building and are wondering what to use for your boxes, this article will explain the basics of building a plastic box and what materials work best for different purposes. Plastic, corrugated plastic, and polystyrene are all popular materials for making boxes, and the same process applies to building these materials. However, you may not be aware of the best practices in corrugated plastic box build, so be sure to read the instructions carefully to ensure that you’re not wasting materials or causing yourself harm.

Plastic

There are many ways to build a plastic box. For instance, you can create a box from plastic sheets. These containers are durable and can survive the high heat from a consumer dishwasher. Furthermore, you can use them for shipping products long distances. Depending on your intended use, plastic boxes can be made sterile and non-porous. They also contribute to a hygienic environment in a clinic. Moreover, you can also create a box of any configuration you want.

Corrugated

The corrugated plastic box build method uses twin-wall sheeting in parallel positions that are uniform in design. These sheets are strong and lightweight, but do not offer the strength or impact resistance of the traditional corrugated steel box. The corrugated plastic sheet is made from polypropylene, a strong thermoplastic polymer with a neutral pH that can withstand all kinds of external conditions. In addition to these benefits, corrugated plastic is easy to handle and fix to wooden frames.

Corrugated plastic

A corrugated plastic box build involves cutting, folding and welding flat sheets of corrugated plastic. The results are durable containers such as totes, bins, divider sets, mailers, and more. A corrugated plastic box build can also experiment with additional layers to add rigidity. Here are some tips to make your own corrugated plastic box. These are just a few of the benefits you’ll enjoy after completing the project.

Corrugated polystyrene

Corrugated plastic sheets are lightweight, water-resistant, and perfect for home, office, or job-site projects. These plastic sheets don’t require painting, and can withstand intense temperatures and environmental elements. They’re also a great choice for emergency shelters and can be easily transported and installed in a variety of frameworks. They can also be used as signage or surface protection.

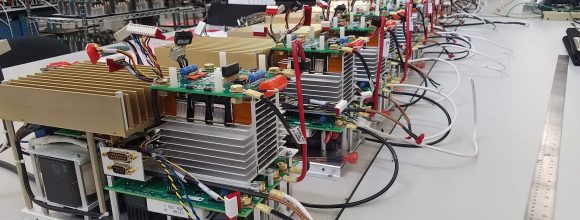

China Printed Circuit Board Assembly Services, A highly efficient manufacturer can reduce your costs by up to 50%. The company will complete the job within a few weeks. The PCBs will be fully tested before shipping.

Corrugated polypropylene

A corrugated polypropylene plastic box is 100% recyclable. Depending on the recycling program in your community, you can recycle your corrugated plastic board. You will need to remove any plastic accessories before recycling. When you’re finished recycling, you can reuse your corrugated polypropylene box for other household items. In addition to boxes, it can also be used as signage or storage containers.

Polyethylene

One of the most common consumer plastics is polyethylene. You’ve likely seen it in products from toys to household goods, and it’s even used for clothing. Polyethylene is a thermoplastic, meaning it can be heated to a liquid and cooled to a solid. Different grades of polyethylene are created by different processing conditions, and they’re all useful for various purposes. Visit https://www.auspienterprises.com/ and learn more about this type of plastic.

Polypropylene

If you are considering using Polypropylene for your next plastic box build, you’ve made a great choice! This versatile material is available in many different forms, and its versatility is an asset for any packaging project. It’s a low-cost, easy-to-manufacture plastic that is highly durable and offers many different applications. Plus, its versatility means that it can be used for everything from opaque to-go containers to toys.