Let Know About 3D Printing: File Preparation For 3D STL Files

Before contacting a 3D printing provider, you should be aware of a particular file format if you consider 3D printing something soon. An STL file is the name of this file type.

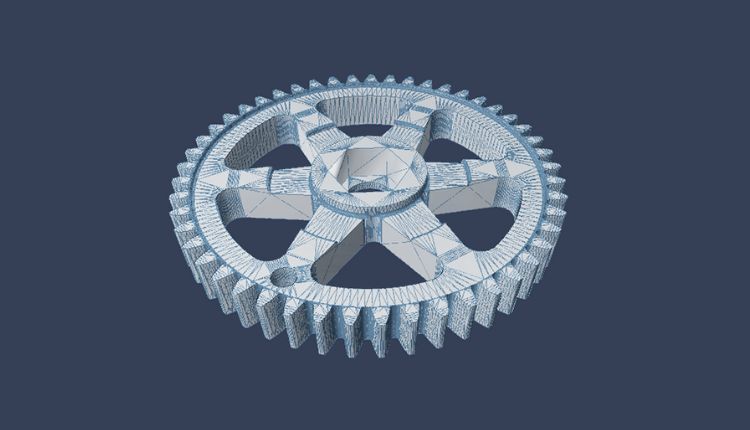

The preferred file type for 3D printing is a 3D STL file. They are employed in stereolithography, an addictisve production technique that has dominated 3D printing for the previous two decades. The STL format has continued to be used as the industry standard for 3D printing since it was first introduced.

Therefore, to correctly print your things, you will require several 3D STL files if you intend to prepare popular 3d models for 3D printing.

If you’re tech knowledgeable, you can convert 3D files into usable 3D STLs to prepare them for 3D printing. We’ll study and demonstrate 3D STL file preparation in this in-depth look at 3D STL files.

Prepare Files

Getting standard STL files ready for usage in any 3D printing program is crucial if you intend to work with them. Current CAD programs can produce 3D STL files for various 3D printing platforms in any orientation.

File Size and Resolution

To create an STL file, end users just need to choose to save the free 3d models as an STL (.stl). In addition, to save time and reduce file size, all STL files should be exported as binary files rather than ASCII files.

Some settings, including those that alter the file’s resolution, may change its makeup. Triangle placement on the model’s surface is also more common in larger 3D STL files. Smaller files typically have considerably simpler geometry.

If you intend to use your 3D STL for rapid prototyping, ensure your files have a minimum feature thickness of 0.020; any fewer results in underdeveloped features on the model. However, some files could require various thicknesses, so verify.

An STL file that is appropriate for 3D printing services should ideally be small in size, including the file size, and shouldn’t provide too many challenges for the service while receiving the file and preparing it for printing. Many 3D printing providers offer instructions on how prospective clients should set up their files for printing.

If There Are Mistakes

Sometimes after being saved and rendered, STL experiences errors. Unfortunately, the 3D printing process is frequently complicated by these flaws.

Fortunately, there is software to solve that issue. The STL Prep module in SpaceClaim Engineer assists in popular stl files. It provides a single answer for safely editing STL and CAD files for subsequent usage in a 3D printer and fixing any obvious problems with them. In the design field, 3D printing is the equivalent of a laser printer in a typical office setting. Its use is rising quickly along with the extraordinary rise of three-dimensional CAD solid modelling. 3D printing provides a quick, significantly less expensive approach to manufacturing concept/prototype models.

Although it has significant economic advantages, this printing complements the more established rapid prototyping (RP) technique. Layer-by-layer models are created using STL data by conventional fast prototyping and three-dimensional printing methods.

Due to their higher initial investment, RP systems are frequently centralized and have a specialized staff that performs duties akin to those of an internal service bureau. On the other side, 3D printers offer simplicity and ease of use that minimizes “departmental delay” because they are more inexpensive, smaller, and suited for installation close to an end user, even on their desk.

When creating a business plan, there are many factors to consider when comparing service provider costs with internal 3D printing costs. However, a company that regularly sends parts to an outside agency could, in contrast, quickly justify the price of a 3D printer while still maintaining internal control and confidentiality.

Conclusion

According to studies, a product six months late to market can lose up to 33 per cent of its potential gross profit. To this goal, design cycles are quickly getting shorter and faster. By facilitating improved communication and collaboration between all parties engaged in the process, free stl files can significantly shorten design cycle times. Speed to market is crucial in today’s society, and 3D printing could provide your products with the essential competitive edge they require.

Users can also benefit from the module’s user-friendly interface, which effectively lets them deal with any primary 3D format used today.

Read also more information https://globalnewsinsights.com